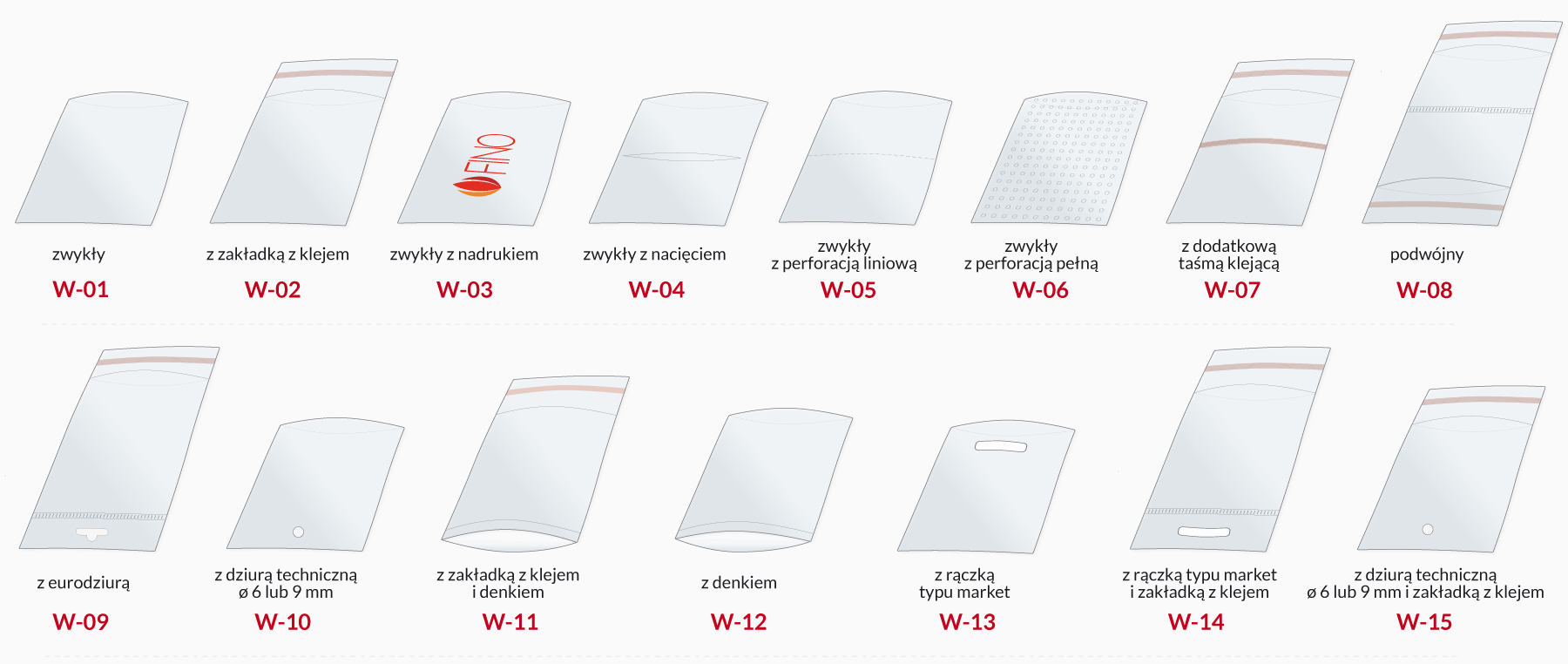

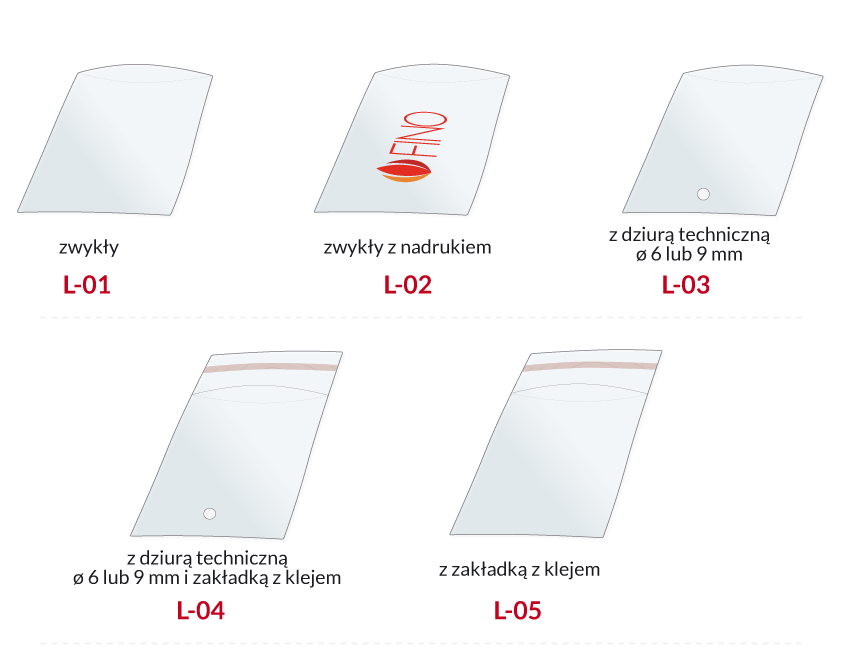

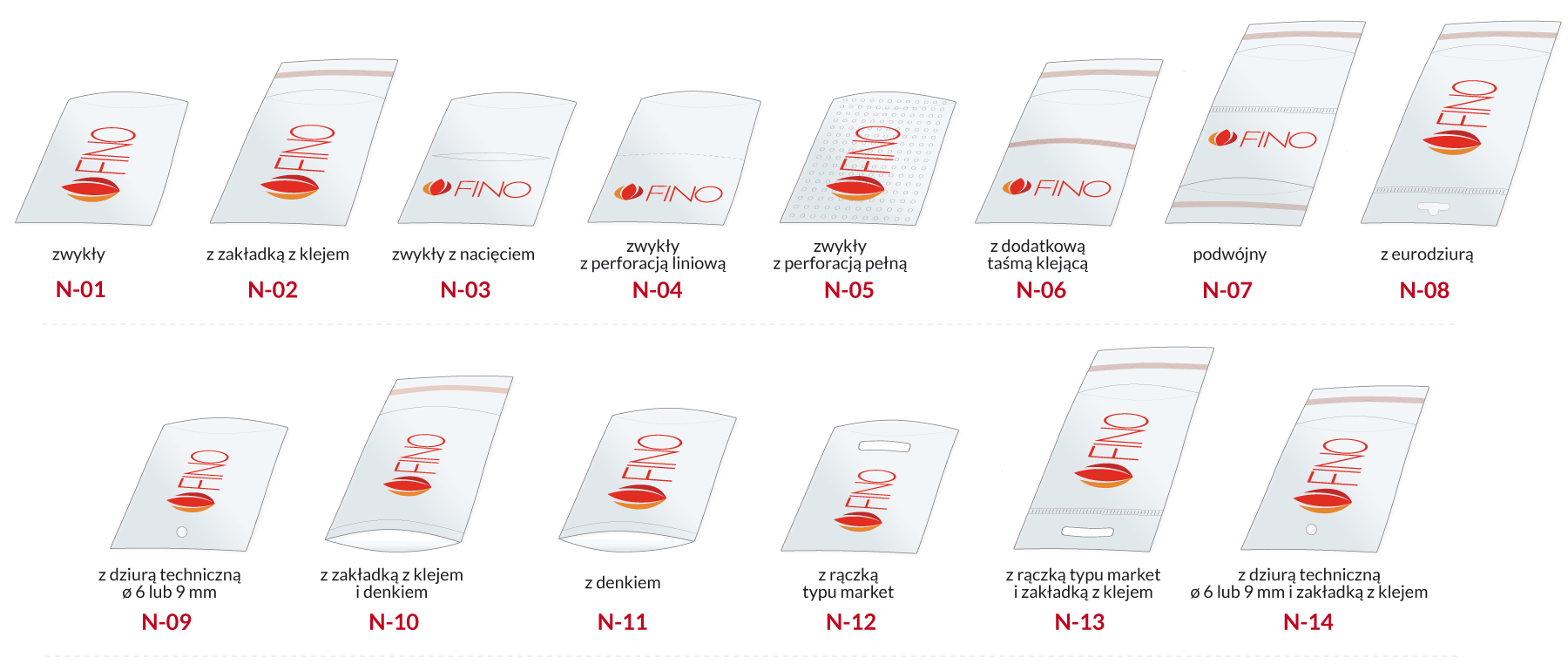

We produce many types of bags using our present machinery. Our long experience in providing packing services has been implemented also into the bag production process. Our first step is to set an objective of packing and next to select a suitable type of film, its thickness, dimensions, and additional parameters.

The minimum production for tailor-made packages without printing is only 1,000 pieces. Owing to this, you can pack even short series into custom-made packaging. The present flexible adaptation of production capacities allows us to produce bags from 27 mm to 1,000 mm wide, and from 30 mm to 720 mm high. The width is the size of a bag where it is open. The production process is subject to continuous monitoring and recording in line with GMP procedures.

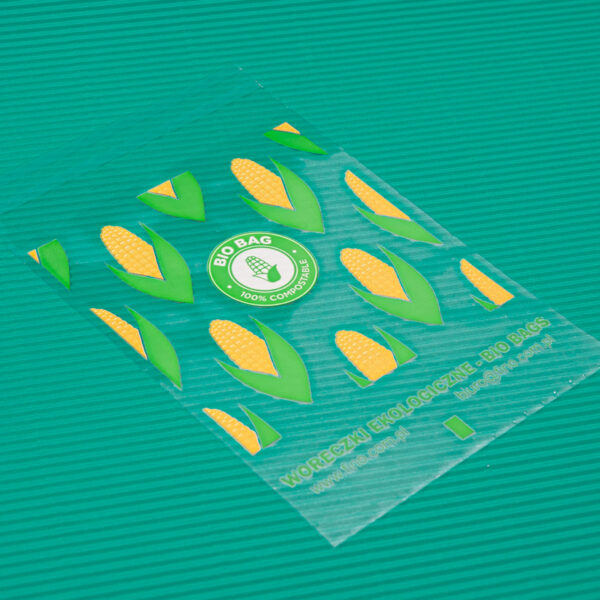

The vast majority of our production are bags made of polypropylene films. We use high quality films that comply with the requirements for products designated for food contact according to regulations applicable in Poland and EU directives. We use film from 15 to 100 micron thick.